Sputter Deposition Systems

In addition to the Royce Deposition System, the CM group possesses three sputter deposition systems, which are described in detail below. For an introduction to sputtering click here.

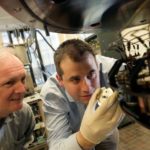

The figures to the right show the group's main sputtering system. It contains 10 bottom mounted magnetron sources and a rotating carousel for deposition of complex multilayer structures with any layer order. This system is unique in the UK, and has a number of novel features including a nanocluster deposition source and an ion gun for surface milling.

The figures to the right show the group's main sputtering system. It contains 10 bottom mounted magnetron sources and a rotating carousel for deposition of complex multilayer structures with any layer order. This system is unique in the UK, and has a number of novel features including a nanocluster deposition source and an ion gun for surface milling.

10 Magnetron Sources (3 magnetic)

10 Magnetron Sources (3 magnetic)- Up to 24 samples

- Rotating carousel for multilayer deposition

- Angled magnetrons for codeposition of binary alloys

- Size-selective nanocluster deposition

- Ion gun for surface milling

- Flow controllers for reactive sputtering

- Range of masks for shadow deposition

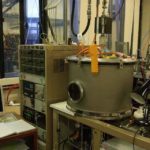

Our second sputter deposition system is similar in design to the first, with bottom mounted magnetrons and a rotating carousel for multilayer growth. This system was designed and built in-house.

Our second sputter deposition system is similar in design to the first, with bottom mounted magnetrons and a rotating carousel for multilayer growth. This system was designed and built in-house.

- 8 magnetron sputter sources (2 magnetic, 2 rf capable)

- Up to 16 samples

- Rotating carousel for multilayer deposition

- Flow controllers for reactive sputtering

- Range of masks for shadow deposition

- C60 evaporation source with in-situ thickness monitoring

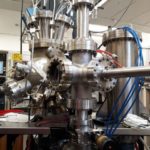

The final sputterer is a quick turnaround UHV system optimised for the deposition of alloys. The 4 magnetrons are mounted at the top, facing down and are angled for codeposition.

The final sputterer is a quick turnaround UHV system optimised for the deposition of alloys. The 4 magnetrons are mounted at the top, facing down and are angled for codeposition.

- Fully UHV system with base pressure-9mbar

- 4 magnetron sources (2 magnetic)

Up to 5 samples per load-lock cycle

Up to 5 samples per load-lock cycle- Angled magnetrons for deposition of quaternary alloys

- Flow controllers for reactive sputtering

- Heated stage to 800°C

- Load lock for quick sample change