Angled Shadow Evaporation System

The shadow evaporator's manipulator can point the substrate in any direction and then rotate about the sample's normal for maximum flexibility.

The angled shadow evaporation system at Leeds was designed in-house to support our research programme on pure spin currents. It is used to deposit lateral devices with extremely clean interfaces. For a tutorial on angled shadow evaporation please click here.

The main chamber contains a four-pocket e-gun source for high-melting point materials and 2 k-cells. The system reaches a base pressure of 10--10 Torr and has a load-lock for fast sample turnaround. Typically it is used to fabricate structures from Co, CoFe, NiFe magnetic electrodes, superconducting V and Pt, Cu and Ag normal metal electrodes. Used in conjunction with the university;s JEOL 6300FS electron beam liothgraphy tool it routinely produces devices with lateral dimensions < 100 nm.

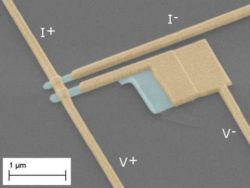

A False Colour SEM image of a completed lateral spin valve.

The three co-axial rotation stages allow the sample plate to be tilted up to ± 90° to the deposition source and have full in-plane rotation of 360°. This allows for any orientation of the lithography pattern relative to the deposition angle from any of the deposition sources.