Materials

Optimised materials

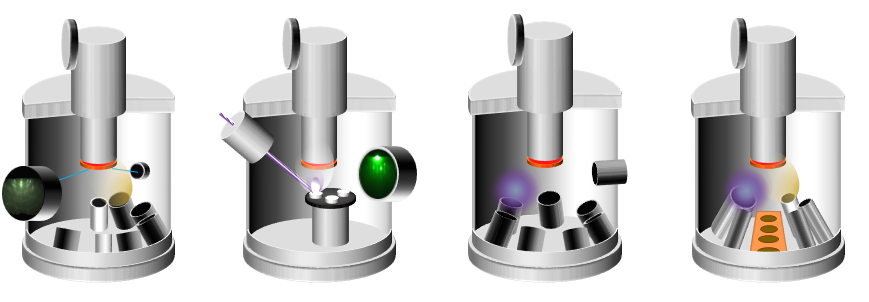

Materials from the Royce Deposition System are available to academia and industry. The system is designed to be flexible, with different types of materials and a range of growth techniques, allowing us to build complex heterostructures with novel interfaces. Within the Condensed Matter Group we have a wealth of experience in thin film growth and dedicated experimental officers who can provide fully characterised samples.

Below are examples of thin film materials that have been optimised in the system.

Bismuth telluride

Topological-organic interfaces

Epitaxial platinum

Fullerenes

Textured sputtered films

Strontium ruthenate

Strontium titanate

Perpendicular magnetic anisotropy

Bismuth ferrite

Magnetic multilayers for skymionic devices

Epitaxial niobium

Superconducting and ferromagnetic devices

Materials by chamber

Topological Materials MBE

Effusion cells:

In, Ge, Se, Bi, Sn

Cracker cells:

Sb, Te

Pulsed Laser Deposition

Targets include:

SrTiO3, SrRuO3, BiFeO3, YIG, ITO

Sputtering

Target include:

Au, Pt, Ir, Ru,

Nb, Ta,

Co, Co62B32, CoFe,

YIG

Organics

Effusion cell:

MnPc, C60, H2Pc

E-beam evaporator:

Pt, Co, Py, Au

Sputter target:

Cu

Publications

Strain-coupled domains in BaTiO3(111)-CoFeB heterostructures

Effects of structural ordering on infrared active vibrations within Bi2(Te(1-x)Se(x))3

Observation of a molecular muonium polaron and its application to probing magnetic and electronic states

M. Rogers, T. Prokscha, G. Teobaldi, Leandro Liborio, S. Sturniolo, E. Poli, D. Jochym, R. Stewart, M. Flokstra, S. Lee, M. Ali, B. J. Hickey, T. Moorsom, and O. Cespedes

Pt and CoB trilayer Josephson π junctions with perpendicular magnetic anisotropy

N. Satchell, T. Mitchell, P. M. Shepley, E. Darwin, B. J. Hickey & G. Burnell

Spin-valve Josephson junctions with perpendicular magnetic anisotropy for cryogenic memory

N. Satchell, P. M. Shepley, M. Algarni, M. Vaughan, E. Darwin, M. Ali, M. C. Rosamond, L. Chen, E. H. Linfield, B. J. Hickey, and G. Burnell