Angled Shadow Mask Deposition

Angled shadow deposition is used to deposit two or more different shaped elements, each of a different material, through the one lithography pattern and without breaking vacuum. The technique minimises the number of potentially contaminating lithography stages and is important when the interfaces between device elements are required to be extremely clean.

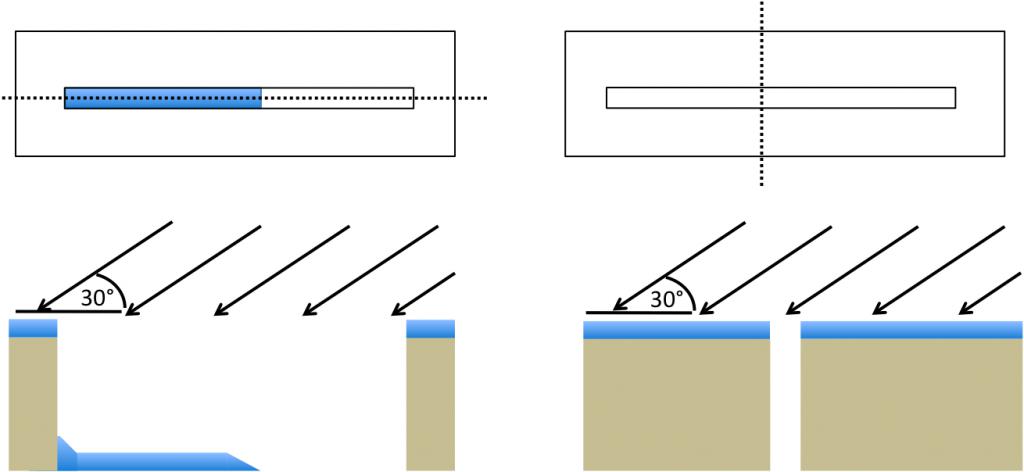

The technique relies upon the fact that when the deposition source is at an angle to the substrate, the deposition rate through a lithography pattern depends critically upon the orientation of the pattern. Consider the lithography pattern shown in the top two images in the figure above. This pattern, which consists of a single trench in the resist, will produce two totally different structures, depending upon the orientation of the pattern to the deposition angle. The bottom left image shows a cross-section of the resist, taken from along the dotted line in the top left image. When the deposition angle is parallel to the longest dimension of the lithography structure, material is deposited into the gap and the resulting structure is shown by the blue material in the top left figure. However, when the deposition angle is perpendicular to the longest dimension of the lithography structure, as shown in the bottom right image, the gap in the resist is too small and no material is deposited.

Careful design of a lithography pattern can therefore be used to deposit two different shaped elements, each of a different material, through the one lithography pattern. In the Condensed Matter group we have used this technique to deposit lateral spin valve structures, which consist of two magnetic electrodes separated by a non-magnetic spacer. To learn more about the angled shadow system in Leeds, please click here.